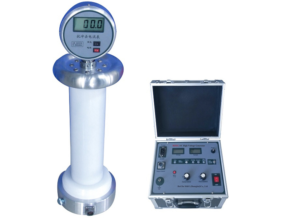

Wrindu HV DC Hipot Tester

Wrindu HV DC Hipot Tester delivers stable DC high voltage, low ripple, and fast protection for safe insulation testing. Compact, accurate, and ideal for field or lab use.

Wrindu HV DC Hipot Tester is designed for reliable and accurate high-voltage DC testing. It uses high-frequency PWM technology to ensure stable output, low ripple, and fast protection response. The tester is compact, lightweight, and ideal for field use. It also supports long working hours with a wide-range AC power supply.

Key Features of Wrindu HV DC Hipot Tester

| Feature | Description |

|---|---|

| High Voltage Stability | PWM closed-loop control ensures stable output. |

| Low Ripple Factor | Ripple ≤ 0.5% for clean and accurate voltage. |

| Fast Protection | Quick response to over-voltage, over-current, and short-circuit. |

| Smooth Voltage Adjustment | Full-range linear adjustment with accuracy better than 0.1%. |

| Precise Measurement | Voltage accuracy 0.5%; current accuracy 0.5%. |

| Direct Discharge Endurance | Safe for large-capacitance equipment. |

| DuPont Solid Insulation | No oil or air filling required; strong and durable design. |

| 75% MOA Test Mode | Easy and convenient arrester testing. |

| Zero-Start Safety | Includes disconnection protection and audio warnings. |

| Shock-Resistant Control Box | Clear, simple interface for safe and easy operation. |

Power and Operation

The tester runs on AC 220V ±10%, 50Hz, with stable performance in all weather conditions. It supports intermittent operation up to 30 minutes at rated load. Suitable for temperatures from 0–40°C and altitudes below 3000 meters.

Technical Specifications of Wrindu HV DC Hipot Tester

| Model | Rated Voltage | Control Box Size (mm) | Control Box Weight (kg) | HV Generator Size (mm) | HV Generator Weight (kg) |

|---|---|---|---|---|---|

| 60/2-10 | 60 kV | 310×250×230 | 5 | 470×260×220 | 6 |

| 80/2-10 | 80 kV | 310×250×230 | 6 | 490×260×220 | 8 |

| 100/2-10 | 100 kV | 310×250×230 | 6 | 550×260×220 | 8 |

| 120/2-10 | 120 kV | 310×250×230 | 7 | 600×260×220 | 10 |

| 200/2-5 | 200 kV | 310×250×230 | 8 | 1000×280×270 | 20 |

| 250/2-5 | 250 kV | 310×250×230 | 8 | 1130×290×270 | 20 |

| 300/2-5 | 300 kV | 310×250×230 | 9 | 1300×290×270 | 22 |

| 350/2-5 | 350 kV | 310×250×230 | 9 | 1370×290×270 | 24 |

Additional Performance Details

| Specification | Value |

|---|---|

| Output Polarity | Negative |

| Voltage Range | 10% to 110% of rated range |

| Voltage Stability | ≤ 0.5% under ±10% grid fluctuation |

| Current Resolution | 0.1 μA (impact meter), 1 μA (control box) |

| Working Humidity | < 90% |

| Storage Humidity | < 90% |

| Working Temperature | 0°C to 40°C |

| Storage Temperature | –10°C to +40°C |

| Altitude | Below 3000 meters |

Wrindu Reviews

RuiDu Mechanical and Electrical (Shanghai) Co., Ltd., founded in 2014, is a global power testing equipment supplier offering transformers, HV testers, cable fault tools and more. With a 50,000㎡ factory, ISO/IEC/CE quality, 200+ staff, and 24/7 support, we provide OEM/ODM and serve 120+ countries.

Wrindu HV DC Hipot Tester offers stable high-voltage output, low ripple, and fast protection. It provides accurate measurements, supports safe direct discharge, and uses durable DuPont insulation. With MOA test mode, zero-start protection, and a shock-resistant control box, it is compact and ideal for field use.

FAQs

What is a hipot test failure?

A failure means the insulation cannot handle the applied high voltage. This shows up as leakage current above the limit or an electrical breakdown such as arcing, which indicates a safety risk.

Will a hipot test damage the product or sensitive components?

Normally, no—when performed correctly, the test is safe. The voltage used is well below the insulation’s design limits. Damage only happens if the test is done improperly with too much voltage or too long a test time.

How is the test voltage chosen?

Test voltage is set based on safety standards like UL, IEC, or CSA and the product’s maximum working voltage. A common guideline for AC testing is about twice the operating voltage plus 1000 V.

How long does a hipot test last?

Most hipot tests run for about 60 seconds. For fast production testing, standards often allow shorter tests of 1–2 seconds with a slightly higher voltage.

What is the difference between AC and DC hipot tests?

AC testing stresses insulation in both directions and does not require a discharge afterward. DC testing gives a clearer reading of resistive leakage and works well for capacitive loads, but the device must be discharged after the test.

What safety precautions are needed?

Safe operation requires strict controls: use interlocked test areas, stay clear during high voltage, confirm full discharge before touching the DUT, ensure trained operators, and regularly check and calibrate the tester.

How does hipot testing differ from insulation resistance (IR) testing?

Hipot tests are pass/fail checks that apply high voltage to see if insulation holds. IR tests measure the insulation’s resistance value in megaohms or gigaohms to judge its condition and detect aging.

What is dielectric breakdown testing?

It is a destructive test where voltage is raised until the insulation fails. Unlike a standard hipot test, it determines the exact breakdown point and is mainly used for design evaluation.

What is a ground bond or ground continuity test?

It verifies that the product’s exposed metal parts have a solid, low-resistance connection to the safety ground. This ensures fault current will safely trip protective devices instead of causing shock.

What can cause a hipot tester to show a false failure?

False failures can be caused by moisture or contamination, poor spacing that allows arcing, incorrect tester settings, or a fast voltage ramp on high-capacitance loads.

How often should a hipot tester be calibrated?

Yearly calibration by an accredited lab is standard. Daily functional checks using known test samples help ensure accuracy and reliability.

You might be interested in