What Is a Partial Discharge Tester and Why Is It so Important?

Discover Wrindu partial discharge testers, their types, key features, and detection methods. Learn how PD testing helps prevent insulation failure in MV and HV systems.

A Partial Discharge (PD) Tester is a diagnostic instrument used to detect and measure partial discharge activity in electrical insulation. Partial discharge refers to small, localized electrical discharges that do not fully bridge the insulation between conductors. These discharges usually occur due to high electric stress, defects inside insulation, surface contamination, or sharp conductor edges.

PD testers help engineers evaluate whether insulation can withstand repetitive peak voltages (Urp) over time. By identifying early insulation defects, PD testing plays a key role in preventing unexpected failures in cables, transformers, switchgear, motors, and other medium- and high-voltage equipment.

Why Is Partial Discharge Testing Important?

Partial discharge often starts silently and intermittently. It usually appears only when the system voltage exceeds the PD Inception Voltage (PDIV). Events such as lightning strikes or switching surges can trigger PD even in normally stable systems.

Each PD event slowly erodes insulation. Over time, this damage lowers the PD Extinction Voltage (PDEV). Once PDEV drops below normal operating voltage, PD continues constantly, which leads to rapid insulation failure. PD testing helps detect this process early and allows corrective action before costly outages occur.

How Does a Partial Discharge Tester Work?

A partial discharge tester applies a controlled voltage to the device under test and monitors discharge signals. These signals may appear as electrical pulses, sound waves, light, or electromagnetic emissions.

Modern PD testers often combine:

-

AC withstand voltage testing

-

High-sensitivity PD detection

-

Digital signal analysis and visual display

High-end PD testers can measure discharge levels from as low as 1 pC up to 2000 pC, with resolutions as fine as 0.1 pC, allowing accurate analysis of micro-discharge behavior.

What Are the Main Features of a Partial Discharge Tester?

| Feature | Description |

|---|---|

| High Measurement Accuracy | Detects very small partial discharge signals, typically from as low as 1 pC, ensuring reliable identification of early insulation defects. |

| Wide Measurement Range | Supports multiple ranges (such as 200 pC and 2000 pC), making it suitable for both laboratory testing and field applications. |

| AC Withstand Voltage Testing | Combines AC hipot testing with partial discharge detection to evaluate insulation performance under real operating stress. |

| Compact and Integrated Design | Small footprint with synchronized voltage output, easy to integrate into production lines or automated test systems. |

| Clear Visual Display | Equipped with an HD screen that presents PD levels and test results clearly for quick analysis and decision-making. |

| Flashover Detection Function | Monitors voltage and leakage current changes to detect flashover early and protect insulation from damage during testing. |

| Stable and Smooth Operation | Ensures reliable performance under high-voltage conditions, reducing test interruptions and improving safety. |

| Data Analysis Support | Helps users analyze micro-discharge behavior and assess insulation condition over time through clear, repeatable results. |

What Types of Partial Discharge Testers Are Available?

| Type of Partial Discharge Tester | Description | Typical Applications |

|---|---|---|

| Offline Partial Discharge Test Device | Tests equipment taken out of service and energized with an external voltage source. Allows precise control of test voltage and stress levels. | Cables, transformers, switchgear, bushings, factory and acceptance testing |

| Permanently Mounted PD Sensors | Fixed sensors installed on equipment for continuous or periodic monitoring without shutdown. | Long-term condition monitoring of substations, switchgear, cable terminations |

| Ultrasonic Partial Discharge Tester | Uses ultrasonic probes to detect high-frequency sound waves generated by PD in fluid or gas insulation. | Oil-filled transformers, SF₆ gas compartments, sealed chambers |

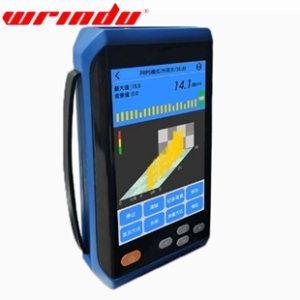

| PD Surveyor | Handheld device for rapid on-site detection of PD activity in energized systems. | Medium-voltage power cables and accessories |

| PD Scanner (PD Scan) | On-line handheld scanner that detects PD in operating MV and HV equipment without interrupting service. | Switchgear, substations, cable systems, distribution networks |

Which PD Detection Techniques Are Commonly Used?

-

Ultrasonic Detection: Best for corona and surface PD

-

TEV (Transient Earth Voltage): Effective for internal PD in metal-enclosed switchgear

-

UHF Detection: Ideal for non-contact PD detection in substations

-

HFCT/RFCT: Enables fast on-line cable PD testing without service interruption

Using multiple techniques improves detection accuracy and PD type identification.

How Can Partial Discharge Be Prevented?

Effective PD prevention starts with good design, material selection, and workmanship. High-quality insulation systems can withstand PD throughout their service life with proper maintenance.

Regular PD measurement helps track insulation health. Trend analysis provides more value than single measurements. Many operators combine PD testing with visual inspections and other electrical tests to estimate remaining insulation life.

Instead of specifying extremely low PD limits during procurement, choosing equipment with enhanced insulation design often delivers better reliability and longer service life.